Made to measure shoes by Buday #2

0March 11, 2017 by Ville Raivio

Last year, with the help of Buday, I set about to try yet another Hungarian shoemaker I had read about but not seen in person. The end result is arrived in the form of the Paris model: a gimped austerity brogue made on the London-last from mid-brown calfskin, with single oak-bark leather soles, double-spaced lacing, piping around the ankle, steel toe plates and clean seamless heelcups. To make them more personal, the shoes were also made to measure and feature bright blue lining along with an undyed welt top and white welt stitching. These small details delight the owner, but won’t stand out like the ever-more popular “luxury” sneakers that feature uppers stamped with brand logos. When having clothes made, there is no need to shout — a commission is already personal without eye-grabbing gimmicks.

The London-last is Buday’s most traditional round toe form: not extended or short, nor narrow or wide, but with a high instep like most Hungarian lasts I’ve tried. The Italian calfskin is very smooth and even, not particularly soft or stiff, and comes in a chocolatey shade. The leather snaps back tp the last’s shape quickly after bending. The all-leather heel stiffener is strong and covers the whole cup. The toe stiffener is likewise strong, though smaller in size. The upper stitching is double-rowed, dense and neat. While the design is on the conservative side, the edges are peppered with gimping and the lacing holes are struck in pairs. Most shoes have an even space between all holes, but the Paris model leaves more room after each pair of holes. These bits, combined with the lengthened and high-reaching wingtip portion, are enough to set the shoe apart. Again, there is no need for shouting with striking patina work or large-scale details if the design is smart.

As with all Hungarian shoemakers I’ve tried, the Buday pair’s sole and welt together are thicker than those found on dressy Italian models. This makes for a bulkier look but lengthens the use before a re-soling is needed. However, when viewed from top-down, most of the pair’s welt disappears under the contours of the last, more so than with other Hungarians. The welt stitch is even in size. The Rendenbach soles come with a fancy finish and large grooves that hide the sole stitches. Unlike Buday’s regular pairs, their made to measure shoes also come with a jar of glue, a brush, two sets of foam heel pads, thicker leather insoles, shoe bags, spare laces, thin leather sockliners plus thin liners with foam inserts. With this arsenal, the customer can modify the fit to his liking and beat any errors made while he took his own measurements. The shoe box is a thin, grey cardboard setup, and the beechy shoe trees have a smooth finish and a very close fit.

Finally, the fit, the most important bit with MTM shoes. My slim heels rise up from most heelcups, but here they remain sturdily in place. Another point is my wider left small toe that usually rubs against the last’s edge. Here it does not. The insteps are securely hugged under the tongues and lacing, and all toes have wiggling room. In short, the fit is, as subjectively as I can say, good after the leather insoles and foam as well as thin liners were added.

Category Footwear, Projects, Quality makers

Anatomy of a Cordings tweed jacket

0March 9, 2017 by Ville Raivio

Cordings, that little shop in Piccadilly, London, sent over a most British tweed jacket for Keikari’s anatomical series. The company has been in the countrywear business since 1839, so I assumed they would know what to offer. It was time to find out about their jacket side as the jacket matches the trous from way back when Cordings was last featured. As before, the cloth is very coarse and many-coloured, heavy by today’s standards at 600 grams per metre, intended for robust wear. Individual threads come in shades of yellow, green, brown, grey, blue.

The cut is a British collection of strong and roped shoulders, nipped waist, three buttons, hacking pockets, flared skirt, notch lapels. The lapels are on the slimmer side at 7.5 cm, with a high gorge, and sharp lines from the buttoning point onwards. A sharp V-shape under the neck leaves little room for the shirt, but does keep the wind at bay. The skirt has a long, rounded line from the buttoning point downwards, and comes flared for a bit of equestrian spirit and room for movement. Hacking pockets are another horsey detail, and a ticket pocket gives more room for the little things in our lives. The breast pocket is cut high and its edges are wide.

In a size 38 jacket, the chest measurement is 54.5 cm inches but ithe piece curves strongly outwards. The shaping is sturdy enough not to leave billowy creases on a willowy chest. As the shoulder seam distance is 45.5 cm, I would describe the typical Cordings shoulders narrow. This is a boon for us pencil necks as most British country jackets have fat and wide shoulders, too wide for the slim Jim. As the cuff girth is just 28 cm, these are slim as well. Same goes for the sleeves on the bicep at 58 cm. In sum, Cordings is different from most countrywear makers because their regular cut is slim, but with enough space for comfortable movement.

The wrist buttons are functioning and the buttons made from urea. The undercollar has a contrast felt and under the lapel are placed two loops for the lapel flower stem. The golden satin lining depicts scenes of hunting, fishing and other masculinely leisurely outdoor pursuits. The sleeves are finished with a contrast stripe lining. Seams are tight and straight, no loose threads can be found, the sleeveheads are high enough, patterns are matched well enough. As presumend, this is the British RTW tweed jacket I will compare all others to. Few makers offer a similar combination of the right cloth, cut and finishing.

Category British Style, Jackets, Quality makers

Anatomy of a vintage Brooks Brothers button-down shirt

6March 5, 2017 by Ville Raivio

Those in the know also know that Brooks Brothers used to make “The” button-down shirt, as was good and proper since they created the first American models. Thing is, style addicts have been decrying the ever-declining make and quality of BB’s button-down shirts from as far back as the 1970s, when the style writer George Frazier opined so. As fate would have it, I found a very old, unused, still wrapped-up BB shirt from one flea market — in Helsinki, Finland, of all places. It was high time to find out what the hey all this shirt talk was about. The example shirt was made during the 1960s in BB’s own factory in America as part of their Makers series. The model is Polo, the original button-down shirt.

First, the cut. Is it billowy and sail-like on the chest, waist and upper sleeve. On this size 15.5 shirt, a European 39, the chest is 63 cm, the waist 56 cm and the upper sleeve 46 cm. This combination hardly flattered anyone, but back in the days smart shirts used to be covered under knitwear or jackets. They could also be slimmed down for the body-conscious man, but just the one and wide cut was faster to make and easy to fit on most men. The extra slim fit was not invented yet, thank the gods of style, and spandex was not the thing to do. Still, the shoulder-to-shoulder seam measurement is 45 cm and similar to what most contemporary size 39 ready-to-wear shirts have. The wrist measures 22 cm and the collar is a true 39 cm one.

Second, the collar. The quitenssence of all button-down shirts is the collar and they shall rise and fall with it. With a back height of 4 cm, pointh length of 7,5 cm and spread of 9 cm, this is The Golden Ratio of the Brooks Brothers button-down collar from the Golden Age of the company. The proportions are mild but enough to make it look most handsome as the collar’s inner structure is extremely soft: no glue or stiffener, just a thin layer of cotton fabric. The collar rolls. It does not chafe or restrict. The same goes for the cuffs.

Third, the fabric. This one has sanforised cotton instead of the heavy oxford weave cotton that made the most famous BB shirts. Compared to contemporary shirtings, this one feels coarse but has a clean, smooth surface. The sanforisation promises less shrinkage with washes and wear.

Fourth, the details. Here is where the halo around vintage BB shirts dims for me. The buttons are ugly yellow plastic and attached shoddily. The buttonholes are far from tight and raised, loose threads abound, some stitching is wonky and hem edges are turned shoddily. Still, the sleeve ends have nice and tight pleats, the longer hem stays tucked and the heavily rounded hem sides look swell.

In short, Brooks Brothers offered great-looking and comfortable collars but the quality of their finishing and the greatness of their cut leaves me unimpressed. The nostalgia value is strong with these ones. Obviously I am making sweeping generalisations here, so reader beware, as I have no intention of looking up and buying dozens of BB shirts just to see how their make differs with time.

Category American style, Reviews, Shirts, Vintage

Made to measure shoes by Buday

0February 22, 2017 by Ville Raivio

Last year, with the help of Buday Shoes Ltd., I set about to try yet another Hungarian shoemaker I had read about but not seen in person. The end result is arrived in the form of the Pismany model: a gimped austerity brogue made on the London-last from mid-brown boxcalf by the Perlinger tannery, with single oak-bark leather soles, double-spaced lacing, piping around the ankle, steel toe plates and clean seamless heelcups. To make the pair more personal, the shoes were also made to measure and feature bright blue lining along with an undyed welt top and white welt stitching. These small details delight the owner, but won’t stand out like the ever-more popular “luxury” sneakers that feature stamped brand logos. In having clothes made, there is no need to shout — a commission is already personal without large gimmicks.

Pictured below, some shots of the pair in the making.

Category Footwear, Projects, Quality makers

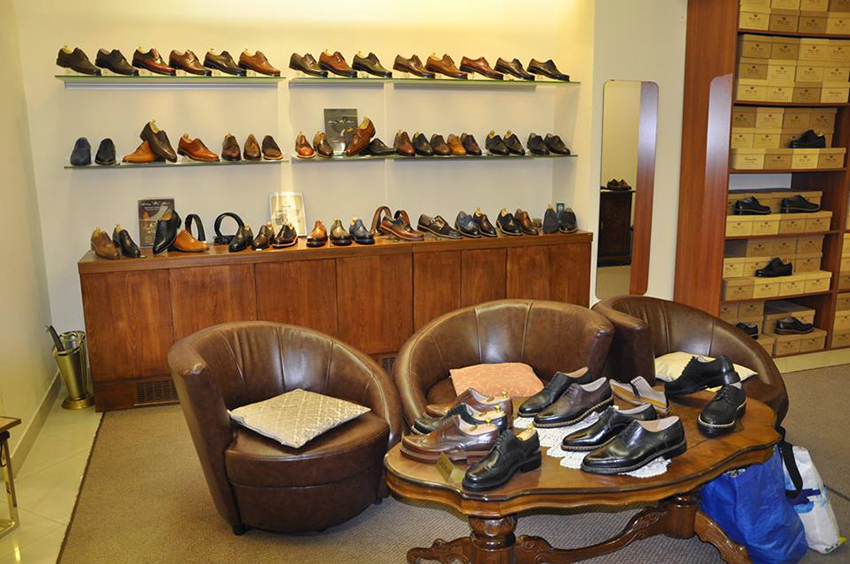

Buday Shoes

0January 18, 2017 by Ville Raivio

Buday is an artisanal shoemaker from Hungary, founded by Gabor Gyöngyösi in 2007. The company has stayed true to the principles of the age-old manual shoemaking where machines are only used to sew uppers and linings. With six shoemakers and two office personnel, 40 shoe models, 20 leather types, 6 welt constructions and 16 lasts, of which eight in regular use, Buday exports a full range of footwear to ten countries.

Sole leathers are oak-bark tanned and made in Germany, most calfskins are German as well. As for a so-called House Style, the company representative tells me that “we are trying to mix traditional styles with modern shoe fashion influences.” Compared to most companies, Buday favours strong colours for its designs and patina work. For exotic leathers, the company sources CITES-certified hides from reputable retailers. Besides ready-to-wear, Buday offers made-to-order, made-to-measure and bespoke shoes. The final option includes a fitting pair and individual shoe trees to boot.

Category Footwear, Quality makers

Copyright © 2013 Ville Raivio