Made to Measure Trousers from Suitsupply

0March 6, 2024 by Ville Raivio

The European men’s clothier Suitsupply has had a customisation program for a few years now. While the service doesn’t include a custom pattern or measuring for the client, there is an option of altering existing patterns for the brave. I braved this choice when SS asked for my thoughts on the service, which works through their web store and offers more than a dozen details, such as the waist for trousers, which can be combined mostly swell. I do say mostly as the waist style I chose couldn’t be combined with brace buttons, which I usually sport. Those must be sewn on by the client.

The service also has more than 100 cloths available, and those can be filtered according to need. Thus, I ended up with a tan fabric from the Rogna mill in a 4-ply traveller wool weave as I trusted it would serve nearly year-round, drape cleanly, and hold a crease like woollen steel. All custom details include helpful photos, and a preview of the end result changes on a preview image accordingly. I knew my trouser size already, which did help with the process, but I wanted to test the service in full. This lead me to go against the usual Suitsupply grain with a model that combines a high waist, looser fit, and a high rise. None of these can be found on the company’s regular trousers. For reference, I measured my most comfortable made to measure trousers and tweaked a size 50.

The end result is pictured. The measurements respond to my wishes, the waist is high, the cut looser. All details came out correctly. The thing which surprised me, though, was the cloth. A traveller wool fabric woven from 4 threads should wear like iron. This wears like cotton, with a heavy disposition for creasing and drooping. If the project was a regular MTM-service, from a book-like fabric bunch, the end result would have been similar. Sample bunches are too small to find out how a large piece of the material wears. Thus, the verdict is positive for Suitsupply’s service and negative for Rogna’s opinion on a “good” traveller cloth.

Category Projects, Trousers, Web stores

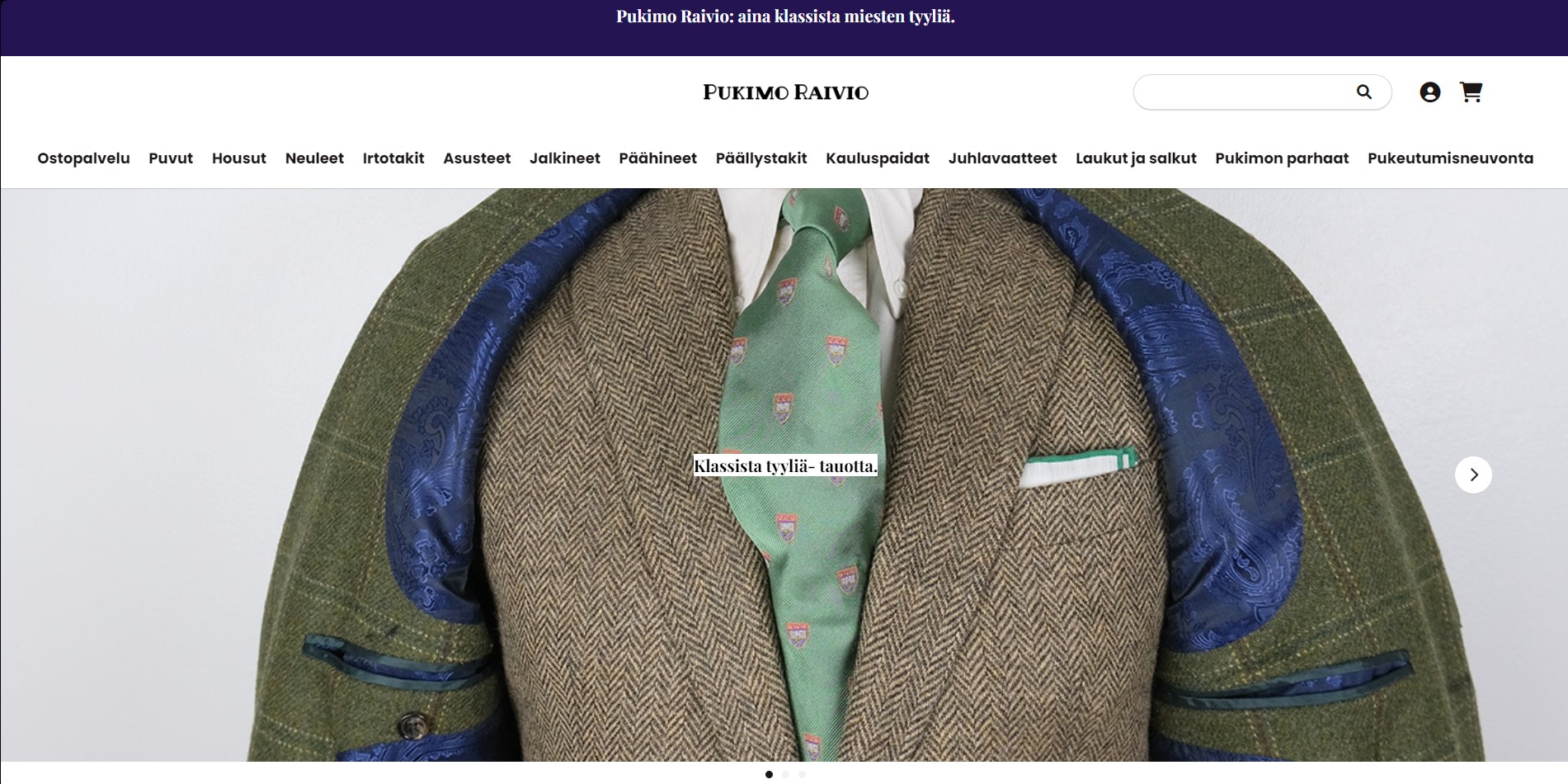

Pukimo Raivio: Men’s Used Quality Clothing and Tailoring

1February 4, 2024 by Ville Raivio

My long-time readers must have noticed the lack of updates. There have been no laurels to rest on, rest assured, as I’ve set up a company and a web store called Pukimo Raivio. The content is in Finnish for now, but if happenstances bring many visitors and enquiries, all content is available in English by request. I do ship worldwide already, so I welcome the reader to visit and send a message if need be. My reasoning for the store was an interest for high quality clothing. However, such pieces usually have high prices and limited availability. Getting them used solves many obstacles.

Pukimo Raivio, or Clothier Raivio, is a web store which specialises in men’s high quality, traditional clothing. This means no skinny cuts, bum jackets or pieces made in dubious factories. European makers are favoured as well as full canvas jackets and suits. The company has no retail space or high expenses, so the prices can be kept low. The range varies according to what I find used or what my readers list on their sales accounts. All clothes are cleaned with a steamer, trousers pressed, shirts washed, and so on, before listing.

My company’s list of favoured makers:

- Alden

- Alfred Sargent

- Allen-Edmonds

- Barbour

- Belvest

- Beretta

- Berg&Berg

- Blarney

- Borrelli

- Brioni

- Brooks Brothers

- Burberry

- Canali

- Cantarelli

- Capalbio

- Carmina

- Charles Tyrwhitt

- Chester Barrie

- Cordings

- Corneliani

- d’Avenza

- DAKS

- Eduard Dressler

- Edward Green

- Ermenegildo Zegna

- Eton

- Etro

- Ezzelino

- Gant

- Geneve

- Gianfranco Ferré

- Gieves&Hawkes

- Giorgio Armani

- Hackett

- Harvie&Hudson

- Herrainpukimo

- Hugo Boss

- Hungant

- Italigente

- J. Lindeberg

- Johnston&Murphy

- Kamakura

- Kenzo

- Kiton

- Lacoste

- Lanvin

- Lardini

- Lawrence&Foster

- LEE

- Lloyd

- Lubiam

- Lutwyche

- Marlboro Classics

- Maurix

- Missoni

- Made to Order

- Moncler

- Nigel Cabourn

- Pal Zileri

- Paul Smith

- Paul&Shark

- Polo Ralph Lauren

- Poszetka

- Prada

- Bespoke

- Ralph Lauren

- Salvatore Ferragamo

- Sand

- Santoni

- Septième Largeur

- Silvio Cattaneo

- Simon James Cathcart

- Stafford

- Steinbock

- Stenströms

- Stetson

- Suitsupply

- Sutor Mantellassi

- Thomas Pink

- Tiger of Sweden

- Tombolini

- Tommy Hilfiger

- Turo Tailor

- Tusting

- Tweed

- Vaatturiliike Sauma

- Valstar

- Vintage

- Welch Margetson

- Yves Saint-Laurent

Or through a translation software in English:

https://www-pukimoraivio-fi.translate.goog/?_x_tr_sl=fi&_x_tr_tl=en&_x_tr_hl=en-US&_x_tr_pto=wapp

Category Vintage, Web stores

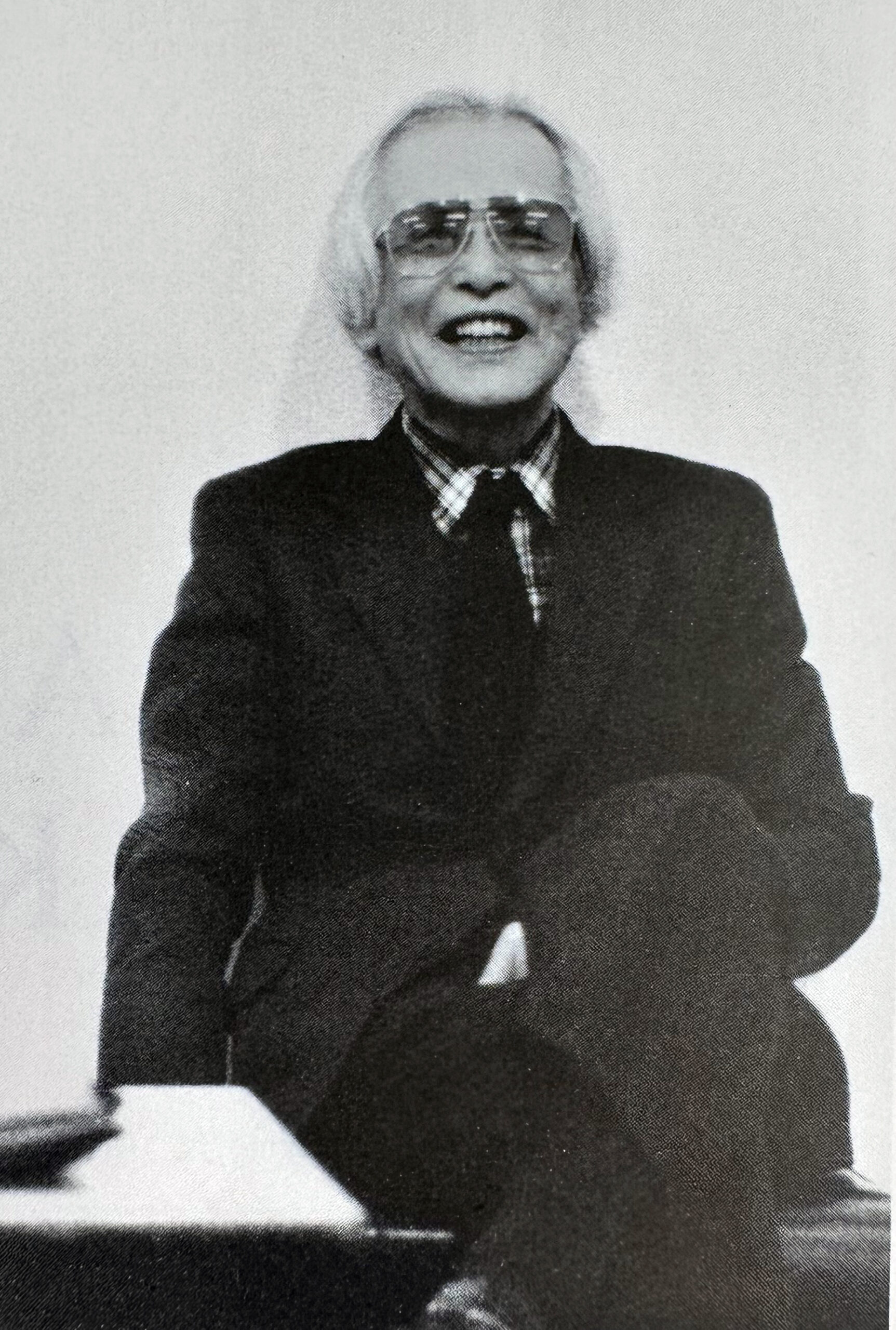

An Interview with Shohei Yamazaki from 30sstyle

5August 15, 2023 by Ville Raivio

VR: Your age and occupation?

SY: I am a Japanese man who turned 55 in July 2023, and I am the webmaster of The30sstyle.com. I work for an advertising agency. It might be a bit peculiar to appear on this blog as I am not a tailor, shoemaker, or shop owner. The30sstyle.com is a site about men’s style in the 1930s and was created out of my passion. I started this site in 2003, so it is almost 20 years old.

VR: Your educational background?

SY: I graduated from Waseda University. I entered the university from Waseda Jitsugyo senior high school, which is affiliated with the university. The school has produced baseball players, politicians, entrepreneurs, business executives, musicians, writers, and many other talents, and I think the free and open minded atmosphere of the school culture encouraged my natural disposition to pursue what I love.

VR: Do you have children or spouse?

SY: I live with my wife. I met her when I was working as a receptionist at Suntory Hall, a classical music concert hall. My wife, who had studied abroad, speaks English and Korean, and she was very curious about foreign cultures, especially the arta. I learned about many works of art from her, the paintings of Rousseau, Matisse, Magritte, Lempicka…and the beautiful glass art of René Lalique, the Dome brothers, and Gallé. I had been interviewed by a person from overseas and she helped me ack then, so she has a good understanding of this style and seems supportive.

VR: …and how did your parent’s and siblings’ react when you first dressing differently?

SY: I grew up with a grandfather, Takao Yamazaki, who was an artist but also worked in the advertising division of Suntory, a brewing and distilling company; a father, Kazuo Yamazaki, who also worked in the same division and led the project to build and manage a classical music concert hall for the same company; and a mother, Masae Yamazaki(Masae Kowari), who was a jazz singer. I spent time overseas for my father’s work soon after I was born, so I was exposed to Western culture from an early age. Wine, whisky, concert halls, jazz… A fine, classic suit would be most appropriate for a gentleman to wear on these occasions. My parents are familiar with such cultures and naturally accept and like my style.

VR: What hobbies or passions do you have?

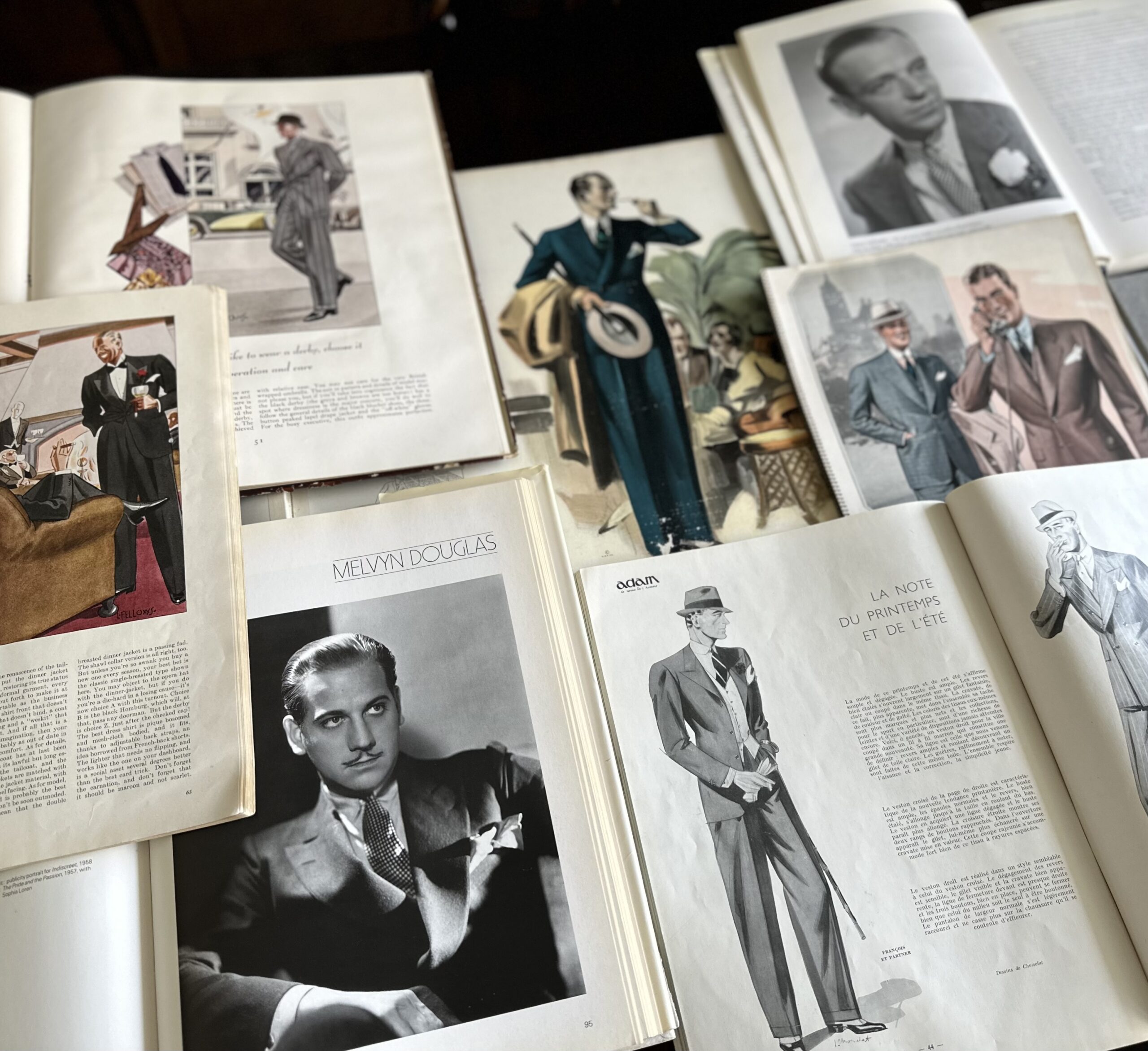

SY: Dressing, enjoying and exploring the style of 1930’s menswear is my hobby, my passion and my life’s work. People from all over the world visit The30sstyle.com, and I often hear that they have become interested in classic and vintage styles. I’m currently preparing to re-design the website, which hasn’t been updated in a long time. I joined Instagram last year and I prefer to post my personal styling there. Instagram brings me new and exciting experiences. I’ve actually met some people through it in real life. I would like to keep sharing my favorite outfits with people, and I am happy if it helps lovers of classic vintage style. Please check my account esky_jp and s.y_esky.

More than just clothes, I also love the Art Deco culture that flourished in the 1930s. I really enjoy seeing Art Deco expressed in graphics, architecture, airplanes, cruise ships, automobiles, household items, artwork, and so much more. In particular, lithographs of Art Deco graphics by A.M. Cassabdre and others, lamps and sculptures by Frankart, tie bars, cufflinks and wristwatches with Art Deco patterns of straight and curved lines, and other items that I fell in love with and bought, give me pleasure just looking at them.

VR: How did you first become interested in clothing, and at what age did you think the 1930s was more interesting?

SY: I first became interested in clothing when I was 13 years old and my father gave me a stadium jacket that he had worn in his youth. From there, I became interested in the American Ivy look and fell in love with traditional American clothing, like Brooks Brothers. As my interest grew, I followed Paul Stuart and Polo by Ralph Lauren, brands where I felt a longing for the British style. I also watched movies like The Great Gatsby and Chariots of Fire, which introduced me to the classic British and American fashions of the 1920s and 1930s. In 1989, when I was 21 years old, the TV drama series Poirot, starring the famous actor David Suchet, started. While watching these movies and dramas, my love for the classic style of the 1930s grew stronger.

In the same year, I came across a store called Draper’s Bench in Shibuya, Tokyo. The shop had chosen the concept of men’s clothing from the 1930s and ’40s, and designed unvented jackets with drapes and wide, high-waisted trousers based on Oxford Bags. I learned a lot from Mr. Hideki Okisaka, who was the director of the shop, about the silhouette, the details, the background…then I was completely immersed in the menswear styles of the 1930s and 1940s. He eventually started his own tailoring business, SAVOY dressmaker. I was so impressed by his pursuit of making clothes in the style of the English Drape Suit, established in the 1930s, that I continued to support him through my website, The30sstyle.com, until his death in 2008. I showcased his suits that I had ordered, and announced his seasonal recommendations and events on the site. I also helped organize meetings to take orders for his suits and offline meetings with him. These were hobbies for me, but I was really doing PR for his business. That was how I got more and more into the style of the 1930s.

VR: Why classic clothing instead of fashion?

SY: There is a famous saying by Yves Saint Laurent. “Fashions fade, style is eternal.”

I think that sums it all up. I’ve enjoyed wearing a variety of trendy outfits, but the only one I still love, which has never faded, is the classic style of the 1930’s. I’m convinced it’s a “style” I’ll love for the rest of my life. There are people all over the world who like this style. And I can immediately imagine what they like. I think that style is something that can convey that “personality” and “world view” to people with the same tastes, and can build lasting friendships. That’s why I’m attracted to classic style.

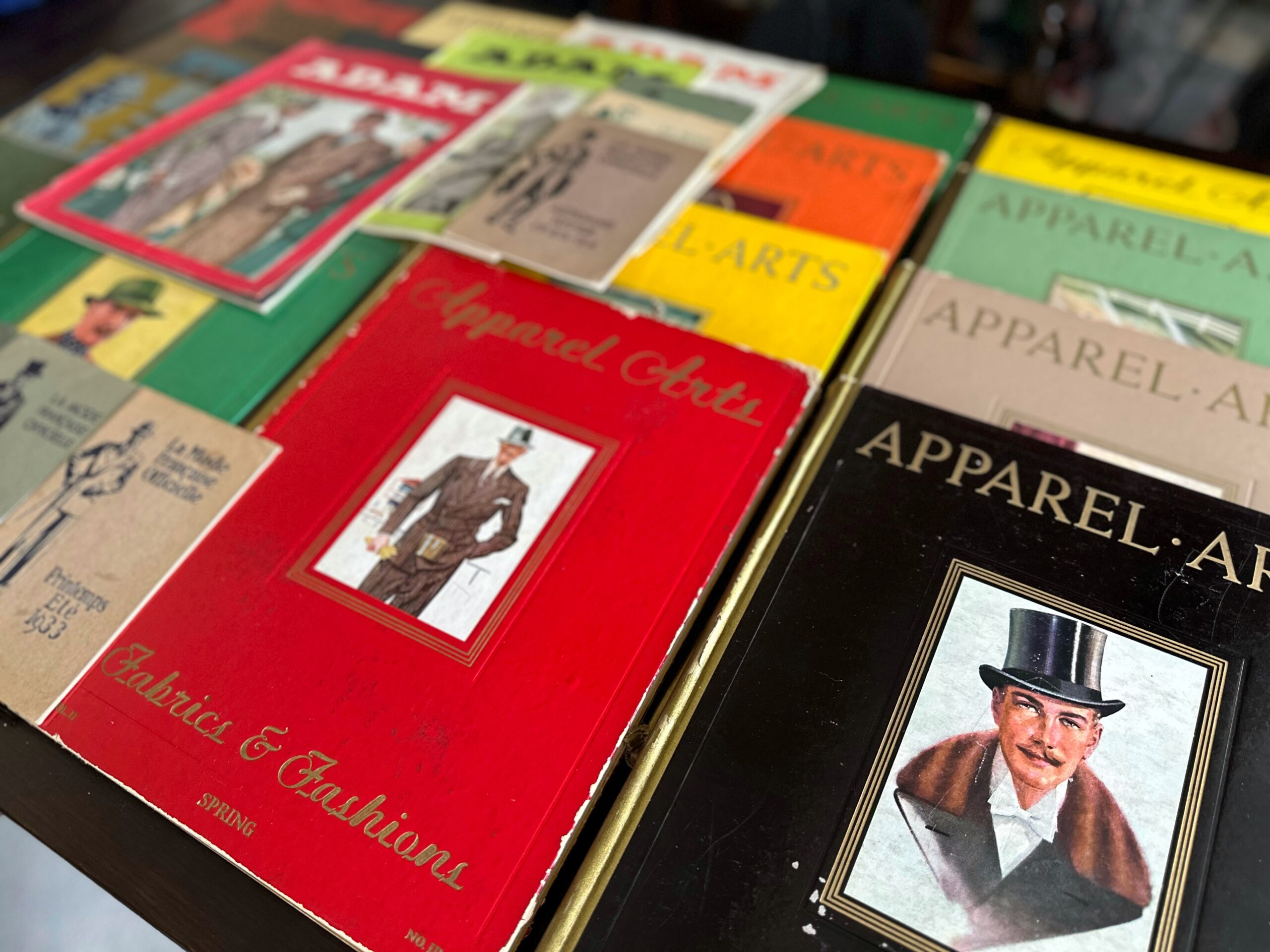

VR: How have you gathered your knowledge of ’30s style?

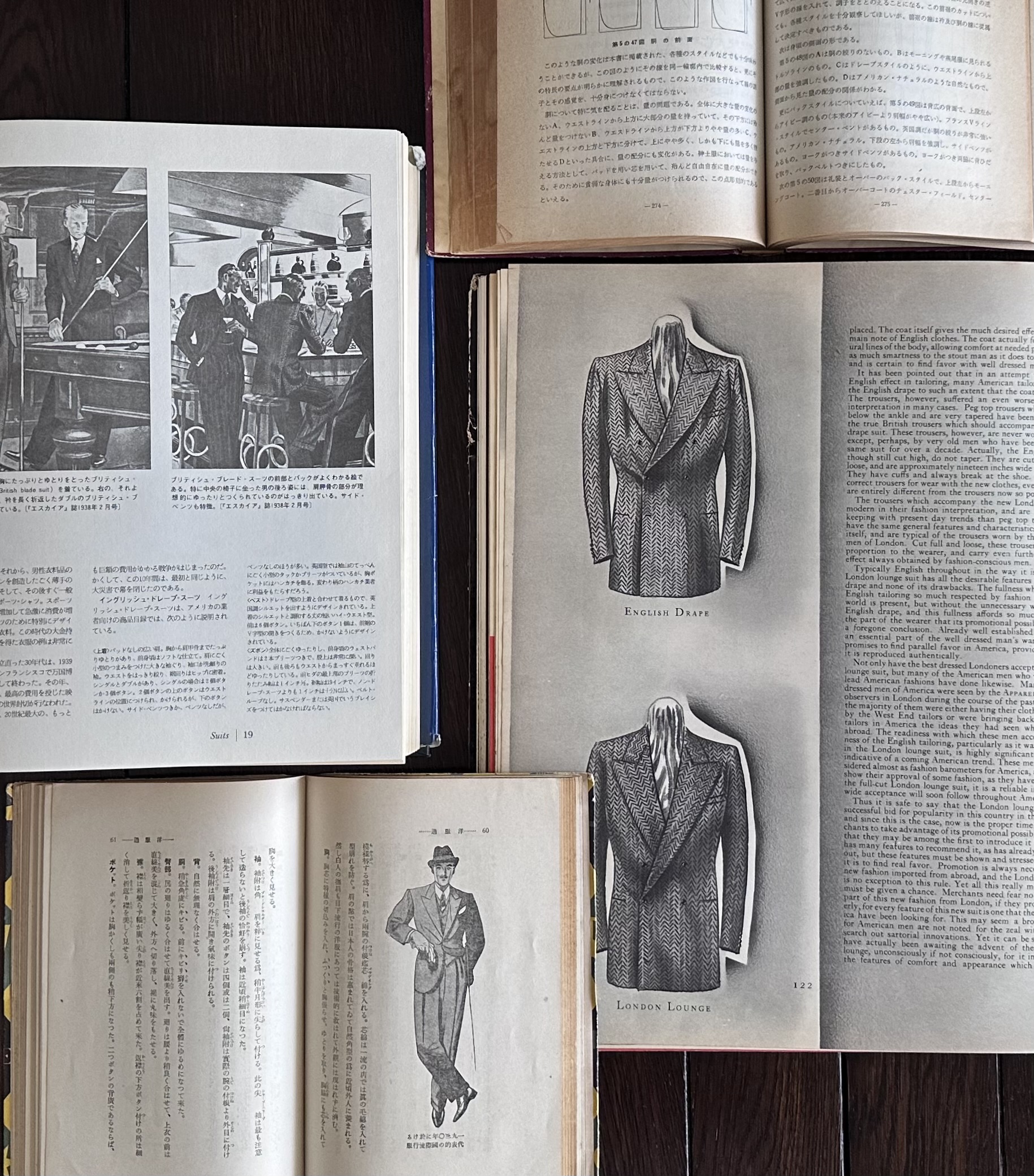

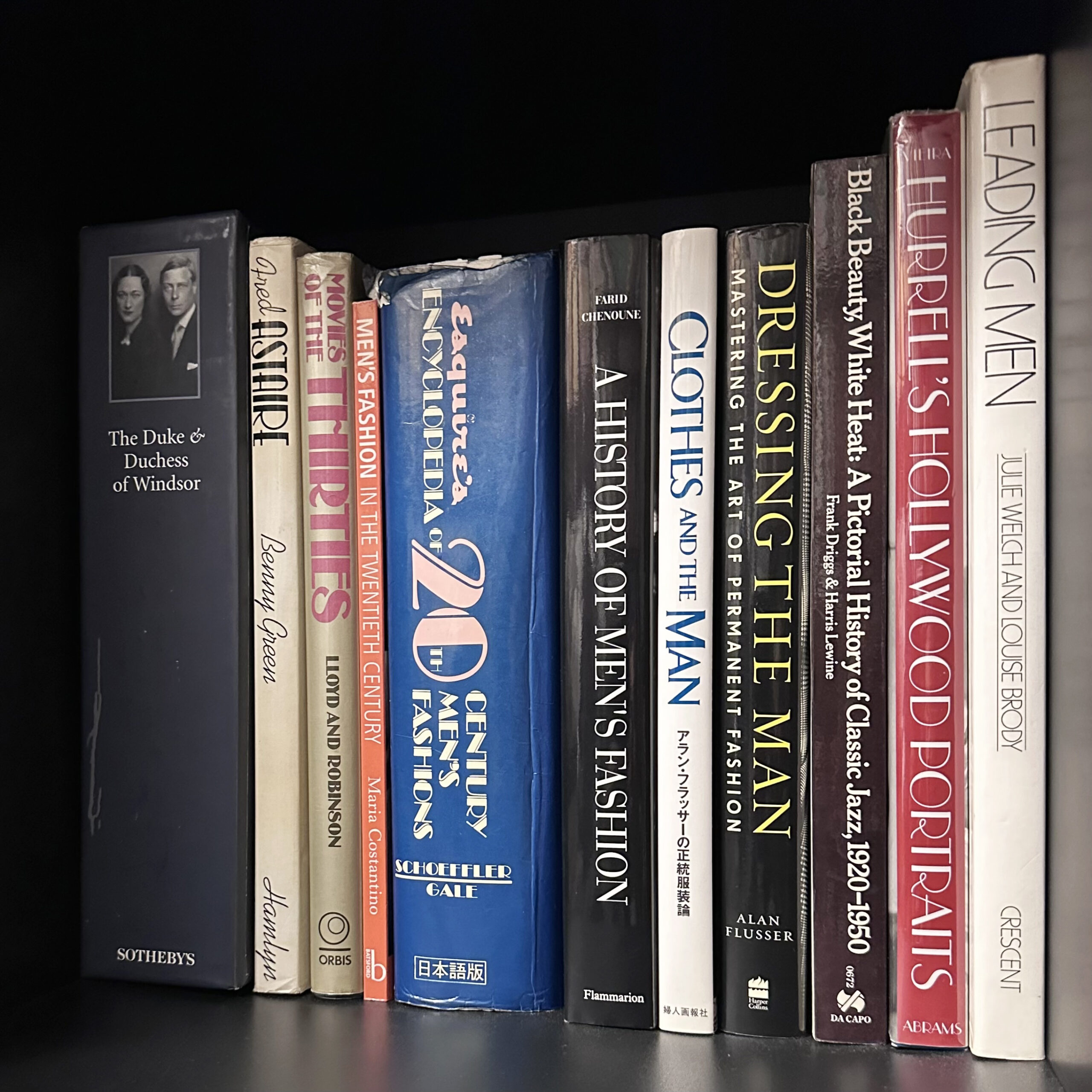

SY: I get my information from books, magazines like Apparel Arts, Adam, and tailoring catalogs published in the 1930s. In the 1980s and 1990s, there was little information available. I visited used bookstores, searched the Internet and bought books, absorbing knowledge about styles and especially the atmosphere of men’s clothing in the 1930s that is not available today. The dozens of books I found became my treasured collection.

VR: How would you describe your own style?

SY: Of course it’s “The ’30s Style”…just kidding, I think my style can be described by the words “classic, vintage and retrospective”.

VR: Do you have favourite tailors or RTW-factories from the 1930?

SY: My favorite RTW shop was Draper’s Bench. But this shop is closed. As for tailoring, it was SAVOY Dressmaker. It was founded by Mr. Hideki Okisaka, who was the director of Draper’s Bench, and I was obsessed with having suits made there for a while. Unfortunately, he passed away. Since then, I haven’t had suits made in that style for a long time. I have also always bought vintage clothes. I like David’s Clothing in Shibuya. This store is one of the leading stores in Japan for British vintage clothing, especially suits and other tailored clothing. The finest vintage suits I bought there are still my treasures.

Looking back, I have seen and worn a wide variety of clothes, including 1930s-inspired clothes, tailored suits, and vintage clothes. Now I’m thinking of producing my own brand of 1930s style suits one day, using my experience.

VR: What do you think my blog readers should know about the clothing which was made and worn in ’30s?

SY: First of all, I want you to know that the suit styles of the 1930s were very different in detail from those of today. It’s said that the English drape style originated when a tailor named Scholte in Savile Row, England, focused on the beautiful curved waist of the Guardsman’s uniform, and adopted it in his suits. The characteristics of this style were described in Apparel Arts from the 1930s and Esquire’s 20th Century Men’s Fashion encyclopedia, as well as in books written by a tailor in Japan at that time. The common characteristics mentioned in these books are as follows:

The jacket has a bust-enhancing silhouette and an hourglass waist. The shoulders are slightly puffed at the sleeve heads with several small pleats, and the trousers are full-cut with lots of fabric. They are worn with braces to hold them up. The rise is high, close to the ribs, and rises diagonally from front to back, a unique design known as the “fishtail line”. The girth of the thigh, knee and hem are loose fitting and fall to the hem. They don’t follow the leg line as closely as modern trousers. According to Apparel Arts of the time, the hem width should be at least 19 inches. This style originated in Savile Row and the West End of London, and spread throughout Europe and the United States to Japan. When worn, this style of suit has a unique appeal that is quite different from today’s suit styles. I hope that more and more people in Japan will discover the allure of the hourglass shaped jacket and full-cut trousers of this style.

VR: What is your definition of style?

SY: Something I will always love and continue to wear.

Something universal to me.

No matter what style you wear, it will become your style as you continue to wear it.

What is important is that it’s something that you can feel the universality of with your senses.

VR: Who, or what, inspire you?

SY: Books about men’s clothing have inspired me the most. I have read many books published in Japan, and I have also collected many foreign books, from which I have learned about the well-dressed men who lived in the 1930s, the actors, politicians, aristocrats, people of culture… The movies produced in the 1930s, the movies that take place in the 1930s, and men’s fashion magazines from the 1930s, and illustrations by Laurence Fellows, Leslie Saalburg, Robert Goodman, HURD, Henssik, and others. The many tailoring catalogs that existed in Europe and the U.S. at that time, and the many wonderful style drawings by unknown illustrators in those catalogs. They all inspire me a lot. Lately, I’ve been checking out people on social media who are into classic vintage style. I especially enjoy the posts from Europe and the US that show really great styles on Instagram.

VR: Finally, how do you see the suit style of Japan?

SY: I think a slim suit with the classic Italian style background has become the trend in men’s clothing in Japan. I am impressed that more and more Japanese men are dressing smartly and stylishly. On the other hand, the classic vintage style represented by the 1930s style, which I have been presenting on my website The30sStyle.com for the past 20 years, is very different from contemporary trends in men’s clothing. It is a style that creates fanatical fans. Nowadays, I think a lot of people prefer this style. I think the trend of more people preferring classic, retrospective and vintage is a very good thing.

Photos: Shohei Yamazaki

Category Bloggers, Interviews, Japanese Style, Men of style, Vintage

Copyright © 2013 Ville Raivio